How To Repair Crack In A Pedestal Crane Base

The aging procedure doesn't just affect us humans; lifting and transport equipment is subject area to fatigue, too. Unsurprising, given how difficult it'south used. And as the slow but steady progression of rust and friction takes effect, in one case-new machines are wheeled into repair and refurbishment workshops around the world on an e'er-revolving carousel. In this way the age-old practice of repair and refurbishment is actually in a constant country of development, with an endless queue of once-shiny machines looking for a new lease of life.

Context for the evolution of the repair and refurb sector can be provided by Dave Wood, managing director at Washington state, USA-based provider of heavy-equipment repair and restoration services Wheco Worldwide Services. Wheco has been in the crane and heavy equipment rehabilitation business for more than 40 years. During this time, the visitor has seen its business concern model evolve many times "as the crane and equipment industry is always changing."

During this time Wheco'due south remit has been broad, performing projects for the military, NASA, the nuclear industry, and the private and OEM sectors, not merely in the USA but around the earth. Having worked with and then many dissimilar types of customer Woods is articulate on what makes a successful working human relationship. "Rehabbing equipment can consist of a consummate unit of measurement or just a portion of the unit," he says. "Information technology comes down to a cost do good – is it more economical and timelier to buy new of refurbish existing. Every customer'due south view of this a little unlike so our approach is customised to fit the need. It is a partnership in the end."

Air current-related piece of work

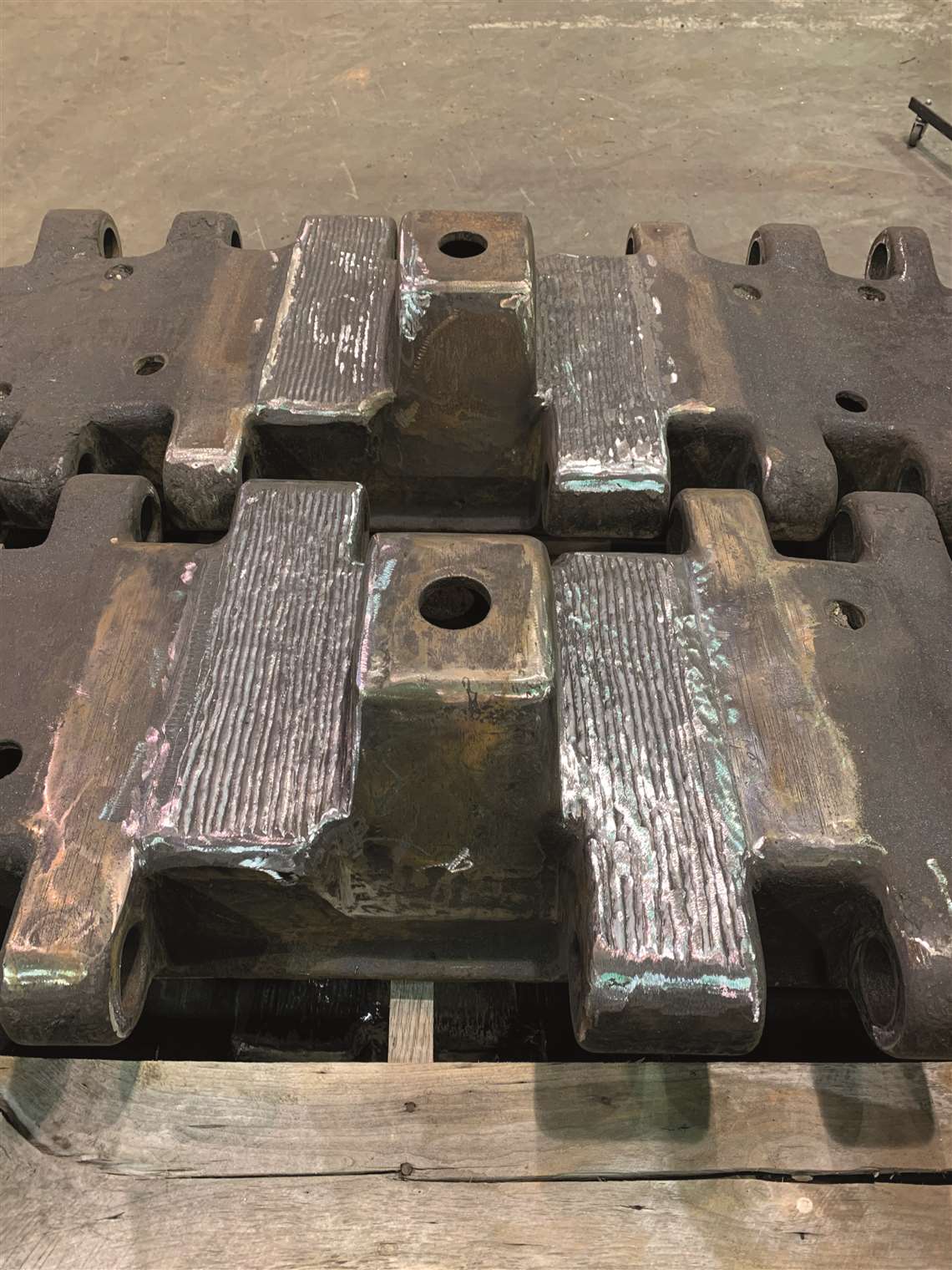

I contempo area of work Wood highlights as being on the ascension is as a result of the booming wind farm industry. "With the work on wind farms involving a bang-up many of the larger cranes in the industry, nosotros are receiving more and more rail and side frame refurbishment requests," Wood explains. "Track refurbishment is not a new idea as it has been effectually since steel tracks were attached to a machine. Anytime yous have metal on metal at that place will be clothing."

Wheco is getting more than rail and side frame refurbishment requests

Wheco is getting more than rail and side frame refurbishment requests

According to Wood, this habiliment is exacerbated by the practice of 'walking' the cranes from site to site. "These large cranes are tasked with not only lifting big components just walking from tower site to tower site," he says. "Normally cranes would exist disassembled for such moves but on wind farms that is not practical so many times the cranes are walked. Some companies accept used SPMTs to transport just that is not the norm.

"Roller paths, rollers and sprockets are high clothing items but at dissimilar wearable rates. Typical roller path wear we see is around ¼". To correct this, we will machine the surface many times to establish a clean base line and and then weld up to original measurements." This is a labour-intensive process only Wood says it is more economic than replacing with new. All rollers are disassembled and re-bushed, the sprockets are cleaned up and the wear surface built upwardly with weld. "The final item which may be at a subsequently date than the roller path or sprocket build upwardly is re-pinning the track pads," Wood outlines. "This can consist of line tiresome the pin holes and re-pinning with new oversized pins."

Forest estimates that a typical track and side-frame refurbishment is approximately 50 percent of new cost and he says it can typically exist turned around in less than sixty days, depending on the condition of the rails assemblies when they arrive and what the customer wishes to address. "Some OEMs try to stock a fix of refurbished tracks to help minimise client down-time, which is a major cost in itself," Wood says.

Manitowoc's EnCORE service creates refurbishment plans based on the private requirements of the cranes

Manitowoc's EnCORE service creates refurbishment plans based on the private requirements of the cranes

Customisation is an arroyo also used by Wisconsin, Usa-based crane manufacturer Manitowoc. The OEM has run its EnCORE refurbishment programme since 2022 and says that each project is unique with its rebuild team creating a refurb plan based on the individual requirements of the crane. The work covers hydraulic cylinders, crane structure, motors and gearboxes, hydraulic, mechanical, electrical systems, and more than. On top of this, the crane's technology is updated to the latest iteration and only Manitowoc-approved OEM parts are used then that customers know their cranes have been restored co-ordinate to the original engineering specifications.

Boom times

Crane booms are a usually refurbished detail, with some repair shops specialising in this type of repair and servicing. "Every bit the boom is the most fragile part of the crane nosotros advise crane owners to only utilise specialists to work on the high tensile steel constructions," advises Peter Klaassen, manager of offshore services at Rusch. Holland-headquartered crane repair and maintenance company forged its reputation specialising in the repair and maintenance of offshore cranes. It expanded its expanse of performance and is now also a crane blast repair specialist. "Manufacturers are non always keen on repairing boom sections equally it can disturb the product line," Klaassen adds.

Although nail repairs may seem specific, they encompass multiple industries and types of machines, every bit Mike Smith, founder and president at Florida, USA-based blast specialist Certified Boom Repair Service, explains, "Although repairs in each scenario are dissimilar, the overall goal must be a repair that is safe, operable and structurally as audio every bit or stronger than the OEM original. With a lattice boom repair, multiple bug must be considered. Boom straightness and overall damage, including corrosion, need to be reviewed and defined. Lattice boom lacing replacement procedures are OEM specified for almost all booms and should exist followed in all cases. Steel tube, course, filler metal class, welder qualifications and welds NDT need to be right and be documented."

Telescopic corrosion

Hydraulic booms tin also suffer similar impairment equally lattice booms, although repair procedures differ from those of lattice booms. "We often see pregnant corrosion fix in on tops of base sections, requiring major repairs," Smith continues. "Most booms accept reinforcement plates on the meridian of the base section in which water is prone to collect. With hydraulic booms being synthetic out of loftier force steel plate, the repair procedures are unlike from repairing a lattice boom of steel tubing structure. However, the core concepts remain the same. The damaged steel needs to be replaced, and the boom needs to be direct. Every project has its ain ready of challenges that embrace all phases of a repair facility'southward power to provide a consummate, authentic, timely and efficient repair procedure."

No thing what part of a crane is being repaired, whether by an OEM or an independent, there is ane unifying principle: safety. "Safety drives this industry," affirms Smith. "A preventative maintenance culture must be implemented to guarantee safety. That goes for the service and repair process every bit much as the operational procedure." This idea of preventative maintenance is echoed by Dave Woods, "With any maintenance, the pull a fast one on is to stay ahead of the wear as one time it gets beyond a certain signal the only alternative may be new."

Lube for longer life

Selecting appropriate greases and properly lubricating components on equipment will cause less wear and tear on machines, thus reducing the demand for more plush maintenance and replacement parts, says Jonathon Roberts, vice president of operations at Lube-A-Boom, a visitor providing lubricants to the heavy equipment manufacture.

Service departments that routinely and properly lubricate their equipment volition come across less downtime, improved safety, and longer habiliment life on components. Proper equipment lubrication volition enhance operator condom. Improperly lubricated equipment will rattle, jerk, and generally non run smoothly. This tin can pb to dangerous working weather for operators on a jobsite.

Proper lubrication will also reduce equipment downtime. By keeping components on equipment properly lubricated with a good grease, you will extend maintenance intervals and continue your equipment working longer. Less downtime means your equipment will be more productive and have a higher rate of return on the investment you put into it. Shutting a crane downward at a jobsite to lubricate it might seem like a major hindrance. But the few hours it takes to properly lubricate information technology will pay off in dividends, rather than facing several days or weeks of unscheduled maintenance to repair any parts that were broken considering of improper or irregular lubrication. Today, many top-of-the-line greases at present come up in aerosol form, which makes lubricating crucial parts of equipment even faster and more convenient.

The full version of this commodity tin can be institute in the December 2022 issue of our sister publication American Cranes & Transport (ACT).

This 'earlier and after' story is a Grove GMK6250L endemic by Brazil-headquartered crane and transport company Locar. The crane fell into the port of Rio de Janeiro and was heavily damaged past saltwater and so had to be rebuilt from the ground up. Locar used Manitowoc's EnCORE repair service. The EnCORE team in Brazil dismantled and washed the crane earlier rebuilding it. All electrical components were replaced and structural repairs were fabricated. The crane was then repainted, load tested and delivered to Locar within nine months. Manitowoc claims Locar saved 40 per cent of the toll compared to purchasing a new crane.

Earlier...

Earlier...

....and later

....and later

Source: https://www.internationalcranes.media/news/repair-and-refurbishment-superb-refurb/8011528.article

Posted by: sankeyonfould.blogspot.com

0 Response to "How To Repair Crack In A Pedestal Crane Base"

Post a Comment